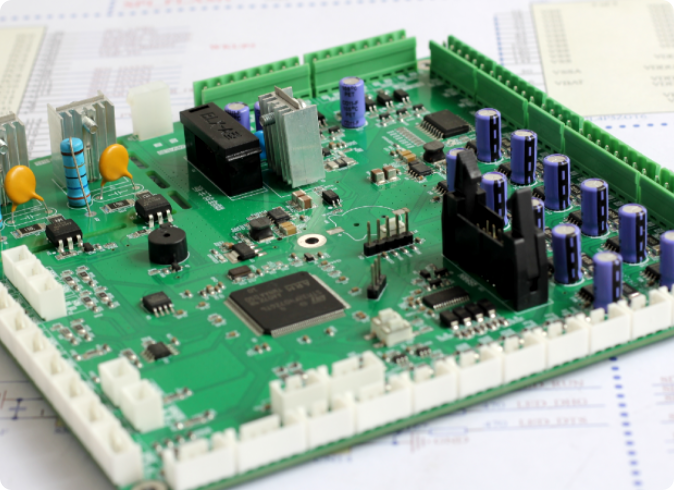

通微服务

产品咨询服务

在过往的很多项目中,我们发现很多问题:有客户对于产品完全不懂,但是现在遇到一个很好的机会。用到电子产品;有对于产品一知半解后,已经开始设计产品,但是因为对于电子产品了解不够深入,导致产品后期投入严重超预算的等。

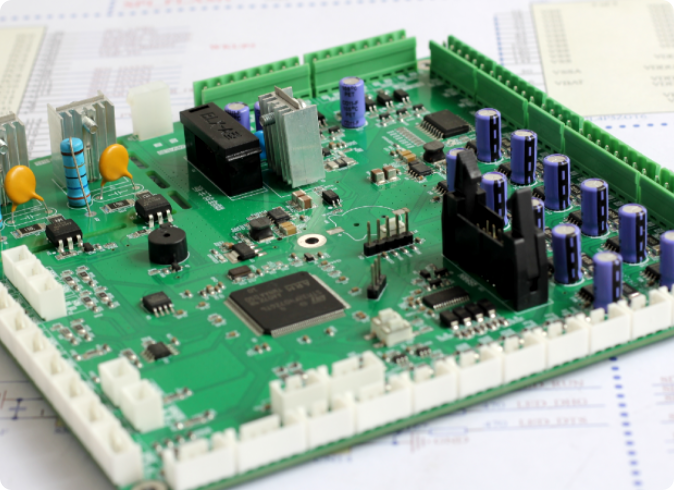

一旦您找倒我们,这些问题都不是问题,我们无偿和您共享我们所积累近20年以上的所有关于电子产品的开发经验、市场经验、生产经验、创业经验等,提供PCB电路设计、stm32单片机开发、物联网设备开发、pcb设计、工业产品设计、嵌入式系统开发、嵌入式开发、单片机开发、物联网开发、电子产品设计等服务,您不用担心我们会有所保留,只要您愿意敞开心扉,我们愿意知无不言。一个电话或者一次会面可以解决您心中所有疑惑,让您满意而归!

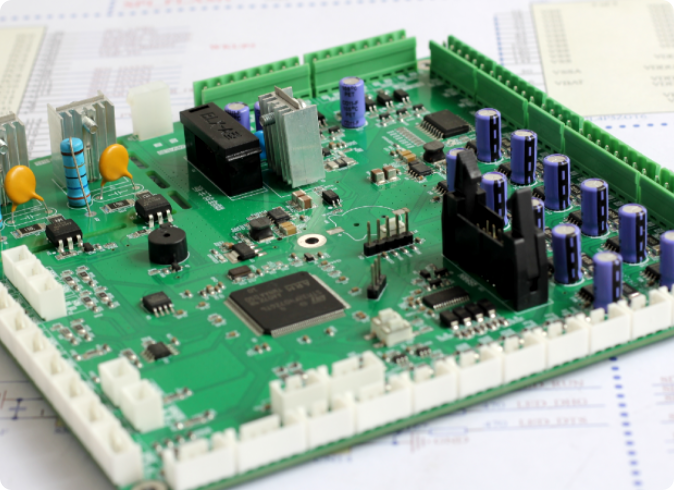

产品设计ODM

运用多年的产品开发阶段,在产品预研阶段把从产品开发,外观外壳设计,软硬件设计,根据批产规模进行生产规划等设计和验证工作。

通微科技的十多人研发团队,虽然不大,但是各个岗位齐备:系统架构工程师,软硬件工程师,结构工程师,生产工艺工程师等。且有着丰富的产品经验,可以让客户少走很多弯路,直接对接公司内部的生产制造,大幅加快产品上市步伐,为客户早日赚取利润。

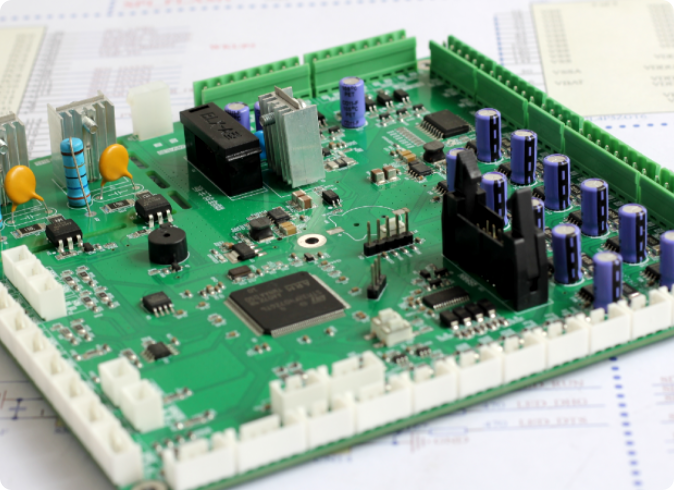

可靠性验证EMC

通微科技拥有自己建立的产品可靠性实验室,有ESD静电试验枪、浪涌测试仪、脉冲群测试仪、高低温交变湿热试验箱等产品可靠性试验设备。可以为客户产品提供EMC&EMI电磁兼容可靠性测试和改进服务、电气安全测试和改进服务、环境可靠性测试和改进服务。

能够有效的将所有的产品开发问题发现在研发阶段,解决在实验室内,尽可能的避免产品上市后再出问题,减少客户损失。而且对于每个不同的行业都有不同的测试标准,如医疗器械、轨道交通等等,需要熟悉标准需求,才能够开发出符合行业需求的产品。

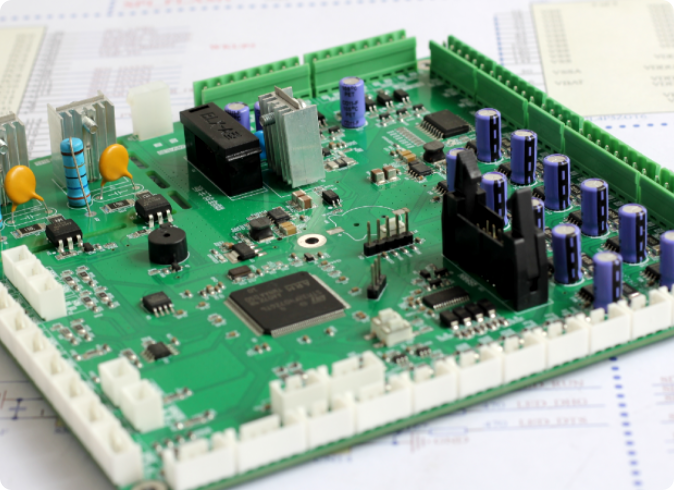

生产制造OEM

对于年产量大于1K~5K以上的产品而言,把产品研发且通过各种实验室测试仅仅是将工作完成了50%,

还需要耗费50%的时间和成本进行批量化生产研发和实施,这一点是很多人忽略导致产品明明已经研发通过,缺迟迟难以量产。

这些工作包括:工艺设计开发,生产流程设计实施完善,自动化工装设计开发,生产软件设计开发,质量控制方案等

专利咨询服务

一般的客户很难判断所研发产品的创新点在哪?有哪些地方需要专利保护?有哪些产品可以申请著作权?

竞争对手的专利保护点在哪等等问题。通微科技已经为多家客户提供了诸如:专利发掘,专利申请,著作权申请,专利查询等服务,对于如何进行专利保护有着深入的见解和处理经验。